- Company

Featured Resource

CLIENT STORYModern Message

To Real Estate

Giant RealPage

- Sectors

Featured Industry Report

EXPERT SERIESManufacturing Software

Report – Part 2

- Research

Featured Resource

FEATURED REPORTThe SEG 2024

Annual SaaS Report

- Tools

Featured Resource

WHITEPAPER20 Factors to Track When Valuing Your

SaaS Company

- Blog

The Global Supply Chain: How SaaS Solutions Minimize Risk

Software Equity Group recently published its 2021 Manufacturing Software Report. We partnered with Industry Expert Paul Lachance, a seasoned manufacturing and industrial technology specialist and established SaaS entrepreneur, to provide the first report in a series of short research pieces focusing on the manufacturing software market. We’ve included a brief snapshot from the report below.

The Global Supply Chain

Manufacturers worldwide are directly impacted by disruptions to the supply chain. COVID-19 has created unprecedented changes to how manufacturers operate, especially as it pertains to the supply chain when the world shut down early in the pandemic.

COVID-19 supply chain came on the heels of 2H19 major disruptions in the supply chain due to the US-China Tariff / Trade Wars. The Suez Canal closure due to a blockage has a reverberating negative impact on the supply chain (an estimated 10% of global shipping goes through this canal).

All these events have caused US manufacturers to re-think and re-shore their supply chain where possible. Manufacturers cannot take their supply chain for granted.

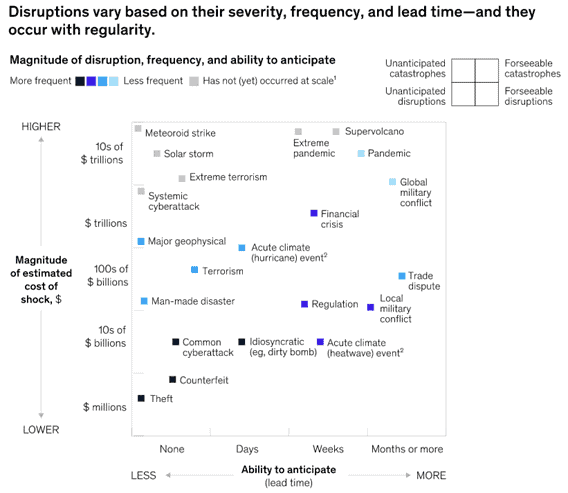

As you can see from the chart above by McKinsey, “extreme pandemic” is at the top of the “magnitude” spectrum. Let’s hope we don’t get a super-volcano anytime soon!

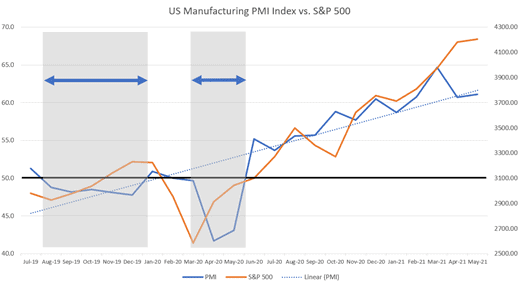

Although not as deep, the 2019 US manufacturing recession (as measured by the PMI) was more than double in time than C19. The PMI Index (US Manufacturing Purchasing Managers Index), released on the first of every month, measures the activity level of purchasing managers in the manufacturing sector. A reading of 50 or greater is considered “expansion”; anything below 50 is “contraction.”

Impacts on Manufacturing:

- “Bullwhip Effect” – a phenomenon that refers to increasing swings in inventory in response to shifts in customer demand as one moves further upstream in a supply chain.

- According to ISM, materials / spares lead times doubled early in the pandemic.

- “Just-in-Time” inventory replenishment severely impacted

- “Stock-outs” (missing a critical spare part when you need it) exasperates profit-killing asset downtime.

How SaaS Solutions Help the Global Supply Chain

SaaS manufacturing solutions help mitigate supply chain risks.

- Minimize exposure to “shocks.” We cannot stop natural disasters, global conflicts, and pandemics, but we can be ready when they happen by building resiliency in our SaaS inventory management solutions.

- When a supply chain shock hits, respond quickly. Intelligent, AI / machine-learning preventive technologies will help balance Just In Time (JIT) inventory management strategies.

- Strengthen your supply chain, do not take it for granted. Build solid transparency, visibility, redundancy (where possible), and management of your supply chain. For example, calculate intelligent and dynamic reorder points for parts and materials based on historical trends, and consider societal and environmental “shocks” (like a pandemic!).

- Harness advantage through digital transformation. SaaS software and beyond. Industry 4.0 technologies from IoT to additive manufacturing (industrial-scale 3D printing) can help mitigate supply chain risks.

- Optimize your supply chain. Numerous SaaS categories can assist in optimizing your supply chain:

- SCM

- ERP

- MES

- CMMS

- WHM, etc.

Download the Manufacturing Software Report here to learn more. The report includes a detailed analysis of the current state of manufacturing, industry tailwinds, drivers of software M&A in manufacturing, a deep dive into the technologies supporting manufacturing, a list of related software M&A transactions, key players within the space, notable transactions, and more.

Please let us know if you have any questions regarding the report, and don’t hesitate to reach out to Paul Lachance to discuss his market insights, manufacturing experience, or consulting services.