The Impact of the Aging Workforce and a Skills-Gap on Manufacturing

A perfect storm of retiring baby boomers, pandemic-related unemployment, and the factory digital transformation combine to create a challenging labor environment.

Software Equity Group recently published its Manufacturing Software Report, in partnership with Industry Expert Paul Lachance, a seasoned manufacturing and industrial technology specialist and established SaaS entrepreneur. We’ve included a brief snapshot from the report below.

Aging Workforce and Skills-Gap Manufacturing

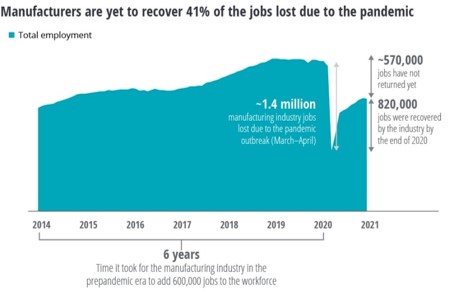

American manufacturing lost a net 578,000 jobs during the pandemic, erasing the last six years of employment gains. At the same time, there are an estimated 500,000 job openings. All while, as a nation, we are still struggling to recover from pandemic-related widespread unemployment. Why are there so many “help-wanted” signs?

None of this should be a surprise; the changing / aging workforce indicators have been around for years. The pandemic combined with record-level manufacturing growth is exasperating this situation.

Aging Workforce: We are an aging population, but even more so in manufacturing. 50% of operations-related teammates are set to retire in the next 7-9 years, taking a tremendous amount of knowledge with them. There are not enough new skilled workers to fill this gap.

Skills-Gap: The digital transformation has changed today’s factories, and we do not have enough skilled workers to run them. As much as we would love to employ women and men who lost jobs in the pandemic-hit industries such as foodservice and entertainment, these people do not transfer well given the changing skills requirements.

Possible solutions to our aging workforce and skill-gap include:

- Educational opportunities to train the next generation of high-tech manufacturing jobs

- Lean manufacturing / best practices – optimizing the operations / team you currently have

- Keep your current team happy: cross-train, flexible retirement, soft-skills improvement working with a diverse-age team, etc.

- Culture change: diversity, equity, and inclusion is critical for manufacturers moving forward – open and retain vast new sources of amazing workers

- Use technology to future-proof your operations

SaaS industrial solutions will help “ease the pain” of manufacturers to combat these headwinds. Together with lean operations / maintenance methodologies, MES, CMMS, ERP, etc. can help ease these macro industry pains and help manufacturers remain competitive.

Download the Manufacturing Software Report here to learn more. The report includes a detailed analysis of the current state of manufacturing, industry tailwinds, drivers of software M&A in manufacturing, a deep dive into the technologies supporting manufacturing, a list of related software M&A transactions, key players within the space, notable transactions, and more.

Please let us know if you have any questions regarding the report, and don’t hesitate to reach out to Paul Lachance to discuss his market insights, manufacturing experience, or consulting services.